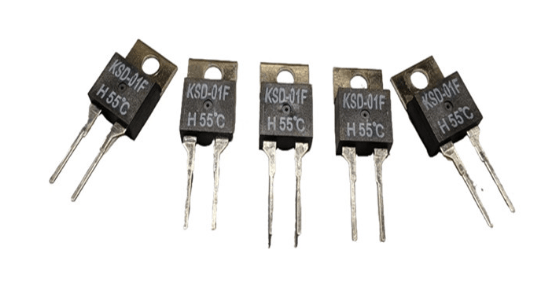

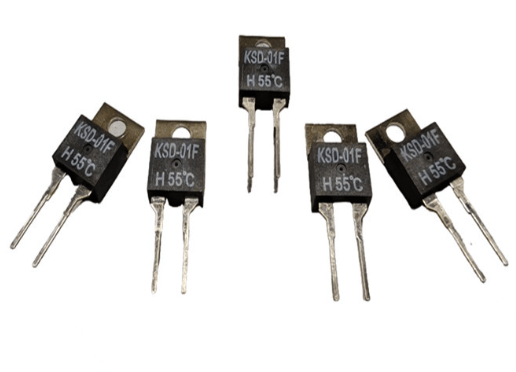

Temperature switches are critical components in industrial and commercial systems, enabling automatic temperature regulation and safety protection. The choice between Normally Open (NO) and Normally Closed (NC) configurations is pivotal for optimizing performance and ensuring operational safety. This article explores the key factors to consider when selecting the right temperature switch type for your application.

1. Understanding NO vs. NC Temperature Switches

- Normally Open (NO):

In its default state, the circuit remains open (off) at normal temperatures. When the temperature reaches the set threshold, the switch closes, activating the connected device (e.g., cooling fans, alarms).

Example: A NO switch in a server room triggers air conditioning when temperatures rise above 25°C. - Normally Closed (NC):

The circuit stays closed (on) under normal conditions. When the temperature exceeds the set point, the switch opens, cutting off power to the device (e.g., heaters, motors).

Example: An NC switch in a bakery oven turns off the heating element when temperatures exceed 200°C to prevent overheating.

2. Key Factors for Selection

a. Application Purpose

- Safety-Critical Systems:

NC switches are ideal for fail-safe applications, such as emergency shutdowns in chemical plants. If power is lost, the switch defaults to the open state, halting operations to prevent accidents . - Temperature Control:

NO switches are commonly used for cooling systems (e.g., refrigerators), while NC switches excel in heating systems (e.g., water heaters) .

b. Environmental Conditions

- Extreme Temperatures:

Mechanical temperature switches with bimetallic strips withstand harsh environments up to 340°C, making them suitable for NC configurations in industrial furnaces . - Corrosive Environments:

Switches with stainless steel or Teflon-coated casings resist corrosion in food processing plants or marine applications .

c. Regulatory Compliance

- Certifications:

Ensure switches meet international standards like UL 60730 (household appliances) or EN 60730-2-9 (industrial controls) for safety and reliability .

d. Cost and Maintenance

- NO Switches:

Generally more affordable for basic cooling applications but require regular calibration for precision. - NC Switches:

Higher upfront costs for fail-safe designs but reduce long-term maintenance due to fewer moving parts .

3. Practical Applications

- HVAC Systems:

NC switches maintain constant heating until temperatures stabilize, while NO switches activate cooling when thresholds are exceeded . - Automotive Industry:

NC switches protect engines by shutting down power to critical components if coolant temperatures rise dangerously . - Food Processing:

NO switches in refrigeration units trigger alarms when temperatures exceed 4°C, preventing spoilage .

4. Installation and Troubleshooting Tips

- Wiring:

Use 0.5–1.5 mm² copper wires for high-current applications (e.g., industrial motors) to avoid overheating . - Mounting:

Ensure proper airflow around the switch to prevent false triggers. Avoid direct sunlight or vibrating surfaces . - Testing:

Use a multimeter to verify NO/NC functionality before installation. For NC switches, check continuity at normal temperatures .

5. Selecting Reliable Suppliers

When sourcing temperature switches, partner with manufacturers that provide detailed technical documentation, rigorous testing reports, and clear compliance with international safety standards. Look for suppliers offering customization options for specialized environments, such as explosion-proof designs for hazardous locations or miniature models for compact electronic devices. Always request samples to validate performance against your application’s specific temperature and operational requirements.

By aligning your choice with application requirements, environmental factors, and safety standards, you can maximize the efficiency and longevity of temperature-controlled systems. Thoroughly review technical specifications and certification credentials to ensure the selected switch meets both functional and regulatory needs.